NEWS CENTER

Millimeter-wave three-dimensional scanning - imaging system

Huachuang measurement and control Huachuang measurement and Control Technology Co., Ltd 2026-01-30 12:00

I. System Introduction

This system is specifically developed for the automated inventory counting scenarios of bulk materials in silos and storage areas (such as ores, coal, grains, chemical raw materials, etc.). Its core relies on the point cloud collection technology of laser radar and millimeter-wave radar, establishing a "non-contact collection, high-precision measurement, and all-scenario compatibility" three-dimensional inventory core capability. The aim is to replace the inefficient and high-risk traditional operation modes such as manual climbing measurement and experience estimation, and precisely solve the material volume/weight measurement problems in complex scenarios such as the enclosed spaces of silos and the open areas of storage areas. The system, with the strong environmental adaptability of radar technology (resistance to dust, rain and fog, and strong light interference) and the high measurement accuracy of 3D modeling, efficiently realizes the core requirements of "unmanned operation, completion within minutes, and centimeter-level accuracy" for inventory counting of silos and storage areas. It not only significantly reduces labor costs but also effectively avoids safety risks such as high-altitude operations and exposure to dust environments. Ultimately, it provides a solid digital support for the refined and intelligent management of industrial material inventories.

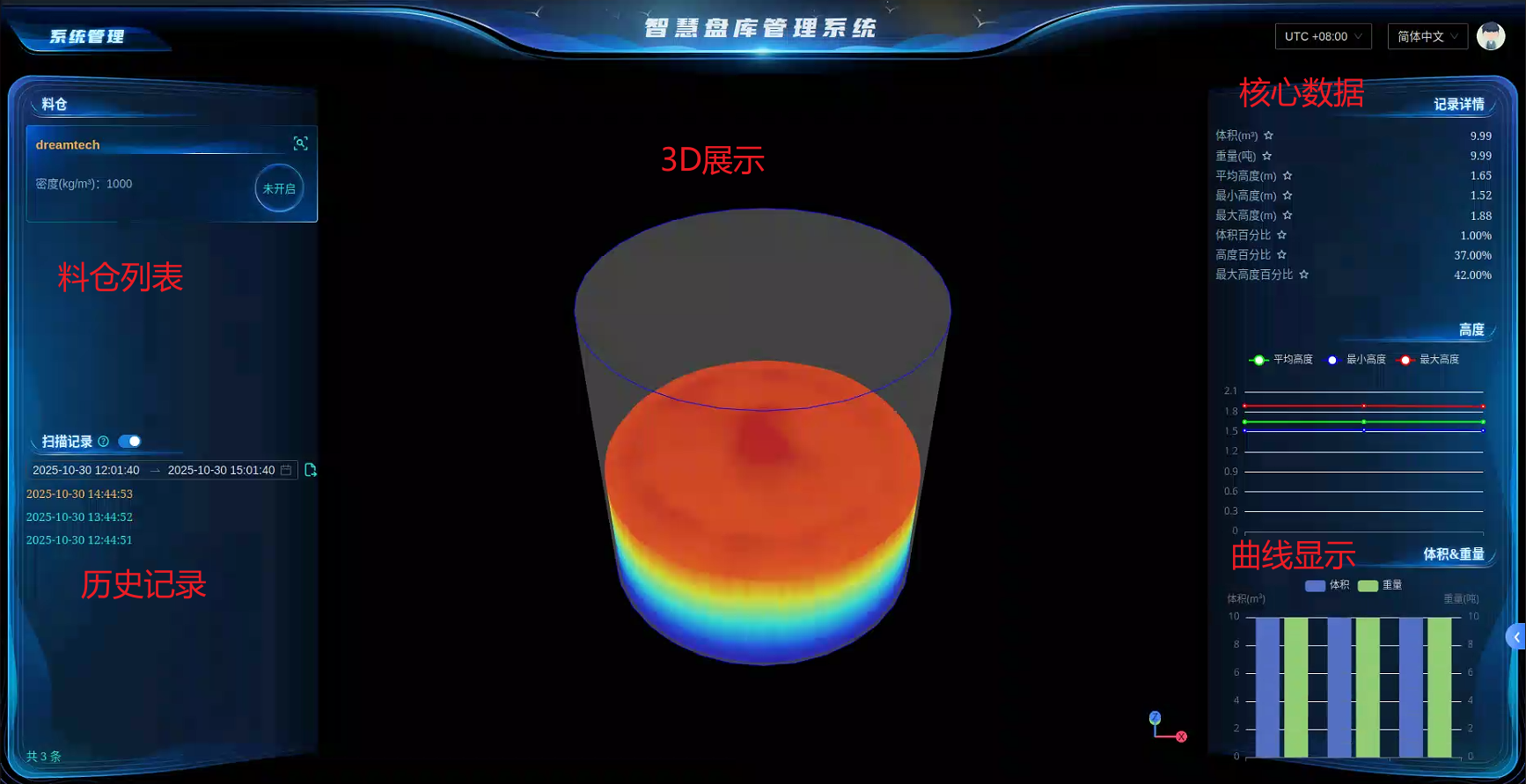

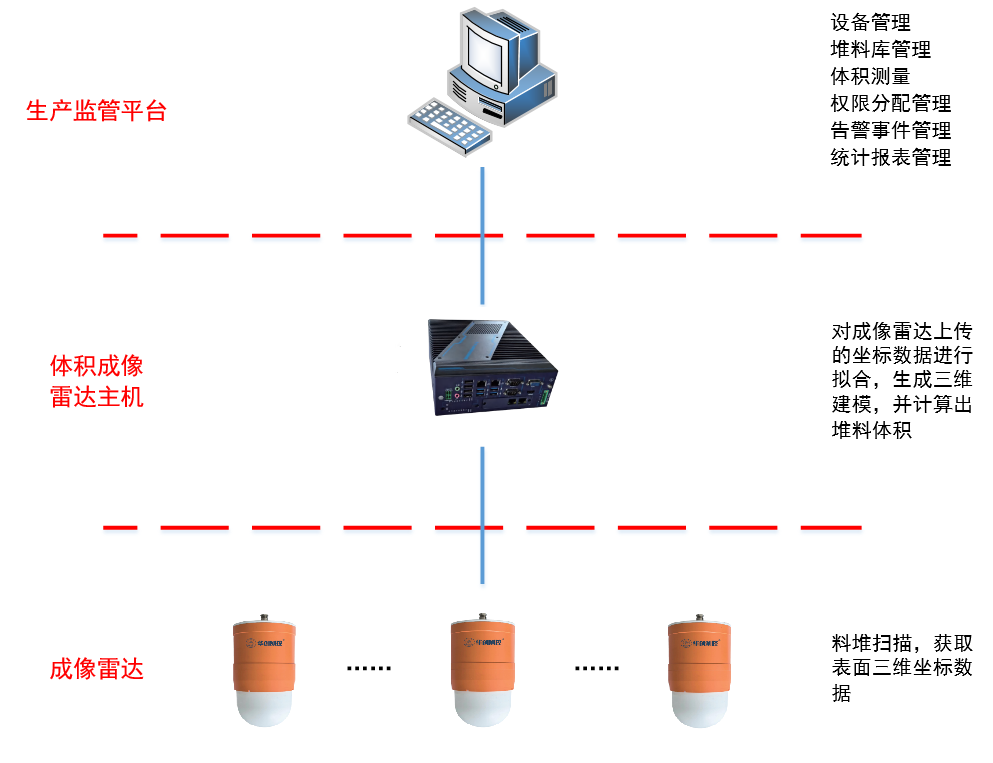

II. Intelligent Data Processing Terminal

The intelligent data processing terminal is a high-performance volume measurement host for stacking materials. It is responsible for reading the point cloud data from the imaging radar and using high-performance algorithms to perform data processing such as point cloud stitching, point cloud filling, point cloud noise reduction, and rasterization. Finally, it outputs the volume of the stacked materials and a three-dimensional modeling effect diagram. It also has functions such as generating reports, drawing historical curves, and configuring scanning plans. It is mainly used in scenarios such as cement, coal, power generation, and grain storage to achieve volume measurement and contour scanning functions, in order to realize industrial intelligence and digitalization construction and provide technical support for intelligent production.

III. Millimeter Wave 3D Scanner

The interior of the millimeter-wave three-dimensional scanner is equipped with a horizontal rotation and vertical oscillation mechanism. The angle range of horizontal rotation is from 0 to 360 degrees, and the angle range of pitch oscillation is from -90 degrees to 90 degrees. During the measurement process, the horizontal rotation mechanism and the pitch oscillation mechanism drive the internal single radar sensor to conduct multi-dimensional and multi-angle measurements. Thus, measurement signals are emitted from multiple angles/directions, and when these measurement signals encounter the surface of the object to be measured, they will be reflected to form various echo signals, which are then received by the radar sensor and used to perceive the surface shape of the object to be measured.

IV. Confirmation of Product Operating Conditions

1. Material properties, such as temperature, dielectric constant, adhesion, etc.

2. The shape of the silo should ideally have a design drawing to facilitate model establishment and volume calculation.

3. Material density. Understanding the density of the material makes it easier to calculate the weight.

4. Installation position: Generally, it is at the center of the silo.

5. Power supply: The 3D radar requires a 24VDC power supply, as well as a 220V power supply, which is used to power the computer and the controller.

6. Will the computers be provided by the customer or purchased by the company? The intelligent data processing terminals are equipped with a network, which facilitates later maintenance and remote debugging.

7. How are the computer, the millimeter-wave 3D scanner, and the intelligent data processing terminal distributed? What is the distance between them? Within 100 meters, a single network cable is sufficient; for distances over 90 meters, fiber optic cables are required.

Installation plan example:

1.The millimeter-wave scanner probe is installed at the site, the intelligent data processing terminal is placed in the main control room, and then a display and the intelligent data processing terminal are connected to display the screen. The millimeter-wave scanner probe and the intelligent data processing terminal communicate via optical fiber.

2. The millimeter-wave scanner probe and the intelligent data processing terminal are all installed on site. An additional computer in the main control room is used to display the images. The intelligent data processing terminal and the computer in the main control room communicate via optical fiber.

If you have any needs, please contact us!

Contact number: 400-851-0898

South of Puhui Street, west of Guangsheng East Road, High tech Zone, Fengnan District, Tangshan City, Hebei Province

Technical support:

Tips

Submitted successfully

Back Index