NEWS CENTER

Monitoring of the tank area of a certain group company in Ma'anshan, Anhui Province

Huachuang measurement and control Huachuang measurement and Control Technology Co., Ltd 2025-11-14 17:47

I. Project Implementation Background

A certain company in Ma'anshan has 5 reaction tanks. They measure the solution of manganese(III) oxide. There is stirring inside and a large amount of steam. Previously, the company's measurement of the liquid levels in each storage tank was basically done through manual observation, which was very time-consuming and labor-intensive.

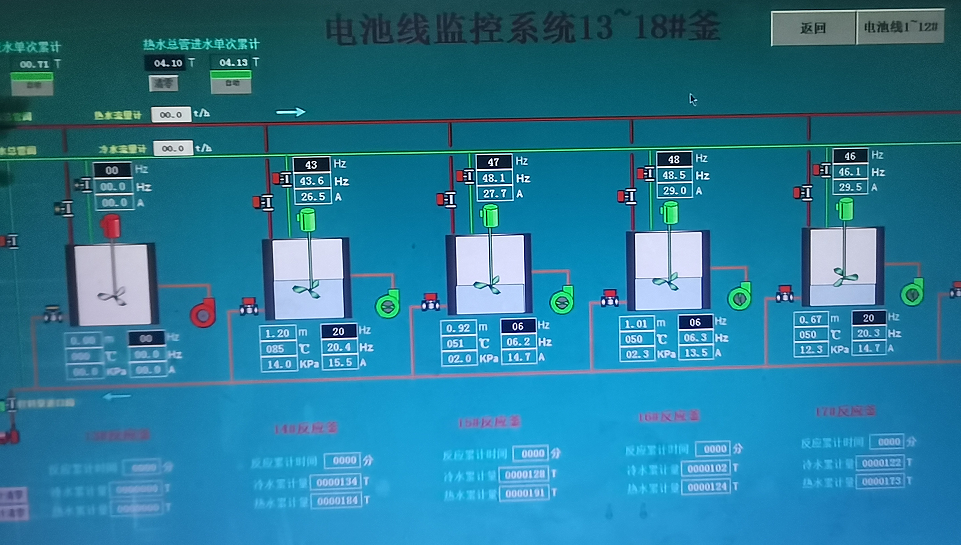

The company got in touch with Huachuang Measurement & Control. Based on the on-site conditions and technical parameters, the HCDAR-81 radar liquid level meter independently developed by our company, with a 4-20MA signal output and a PLC system connected, displays data on the computer screen and triggers upper and lower limit alarms to control the material input and output of the valve. This has initially met the company's requirements for liquid level detection. According to the on-site conditions and technical parameters, the HCDAR-81 radar liquid level meter independently developed by our company, with a 4-20MA signal output and a PLC system connected, displays data on the computer screen and triggers upper and lower limit alarms to control the material input and output of the valve. This has initially met the company's requirements for liquid level detection.

II. Project Implementation Scale

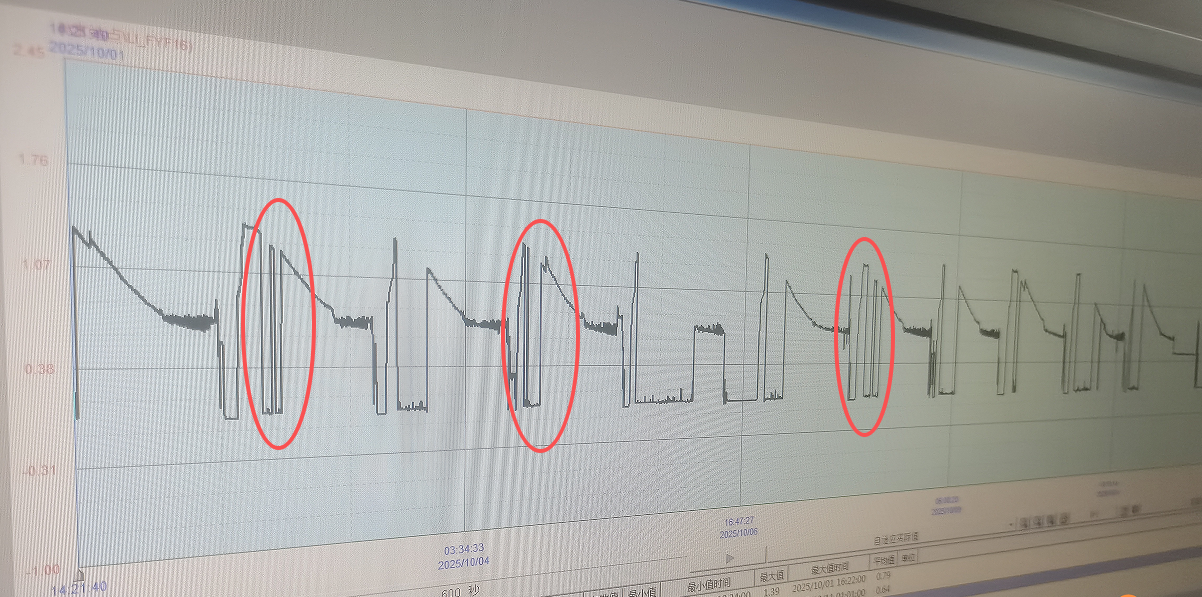

In September 2025, the company got in touch with Huachuang Measurement & Control. They reported that there was a data fluctuation in the radar level gauge. The on-site data of the radar level gauge would return to 0, causing an alarm. The on-site display and the transducer signal would both return to 0 simultaneously. Later, when they opened and inspected the installation of the level gauge, they found many water droplets on the ball surface. Moreover, as the reaction heat of the medium in the on-site reaction tank was released, when the temperature increased, the data of the radar level gauge would also fluctuate. As shown in the following figure:

![]()

After our company's R&D and technical team conducted research and analysis on this situation, due to the on-site working conditions including stirring, a large amount of steam, and the maximum measured medium temperature being around 85℃, the initial solution provided is as follows: The fault output mode of the radar has been changed to remain unchanged. The two parameters of the lowest and highest delay frames inside the radar have been adjusted to 252, which has improved the situation somewhat. However, occasional data jumps still occur occasionally.

After further improvement by our company's R&D team, including modifying the calculation method of the radar program, conducting cross-checks and amplitude threshold tests, and upgrading the radar version on-site, the radar was successfully operated with accurate data measurement and no fluctuations occurred. This not only solved the measurement problem of the radar but also perfectly met the production process requirements of the customers.

The historical curve of computers has run smoothly without any sudden jumps.

If you have any needs, please contact us!

Contact number: 400-851-0898

South of Puhui Street, west of Guangsheng East Road, High tech Zone, Fengnan District, Tangshan City, Hebei Province

Technical support:

Tips

Submitted successfully

Back Index